Analysis of common faults in hot runner system

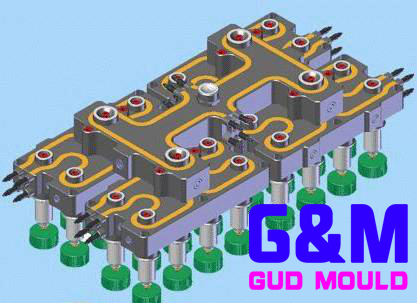

Compared with ordinary flow channel molds, hot runner mould have significant advantages such as saving time and materials, high efficiency, and stable quality. However, its wide application has been affected by their failure in use. With technological advancement of mold industry, hot runner mould has made great progress in flow channel melt temperature control, structural reliability, hot runner component design and manufacture, which makes hot runner technology regain people's attention and favor. First, residue at the gate is protruding or flowing, and surface appearance is poor. Main reason Gate structure selection is unreasonable, temperature control is improper, and there is a large residual pressure in the melt of flow channel after injection. Solution 1) Improvement of gate structure . Usually length of gate is too long, which will leave a long gate material on the surface of plastic part. If...